Porcelain Insulator News

by Elton Gish, NIA #41

Reprinted from "Crown Jewels of the Wire", January 1992, page 9

From the last several "Porcelain Insulator News" articles you may

think that most of the activity has been with multipart porcelain insulators.

Indeed, there has been a lot of hurried activity in that section of our hobby,

as all of us have been scrambling to add another rare "boat anchor" to

our already bulging, limited floor space. Too bad the walls are not strong

enough to place these heavy pieces on multiple shelves like so many glass

insulators enjoy. Since we have temporarily forgotten about unipart porcelain,

news of new finds, none the less, keep piling up. This month we will try to make

a dent in that pile.

Jim Crandall works for Commonwealth Edison Co. in the

Chicago area. He was recently on a routine inspection at the Fisk Generating

Station in Chicago when he had to detour through a seldom used and dark

passageway, using a flashlight to find his way. Partway down the passage someone

said, "watch your head". Jim pointed his flashlight upward to reveal a

concrete shelf with white insulators cemented on wooden pins. His guide through

the dark passage said that this room was the old 25 cycle, 4 Kv room that was

built around the turn of the century!

Jim returned later and retrieved a few of the two types of white insulators.

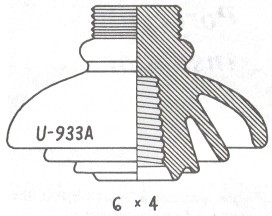

He sent me one of each type that he found. One is a two-piece glazeweld U-933

with an ink stamp on the top firing rest which reads "TESTED MAR 27

1911". It also has the "VICTOR/R=oo" marking inside the small

size insulator logo. The wooden pin does not have threads; instead, there are

circles cut into the pin so the insulator could be fixed on it with sulfur.

The

other insulator is a very unique style, and the only unipart porcelain

insulator with four petticoats. There is nothing like it in Jack Tod's U-Chart,

so we will assign it, U-933A (see photos on following page). It is obviously

older than the U-933, and it surely dates to the original installation. As you

can see in one of the photographs below, it has the incuse date,

"10-23-03" on top of the crown. This is the same marking style used by

Imperial Porcelain Works. Jim has another one with the date, "11-9-03", and he says that only a few of

them were marked. The crown is not threaded, but rather grooved. We can only

guess as to the purpose of the grooves. The grooves may have been used as an aid

to cementing a metal cap, but there was no evidence of cement being used in this

service. There is a copper wire holding copper straps on either side of the

crown which were used to secure a copper bus bar. The bus bar was removed many

years ago. The U-933A has evidence of a tar-like cement in the pinhole.

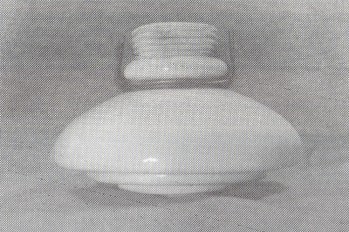

News from Jim Crandall reminded me of a photograph that Mike Guthrie sent to

me in late 1989. This photo, shown below, is of a multipart insulator

that is in Jim's collection. Since it was intended for use in a substation with

a tapered, sanded pinhole for cementing in place, we will not assign it a

M-number; however, I thought that you would like to see this jewel -- too bad we

cannot show it to you in color. It does not have any markings, but it is a

beautiful dark blue!! It is nearly 38" tall. dwarfing the 4-1/2" tall

CD 145 H.G. Co. next to it.

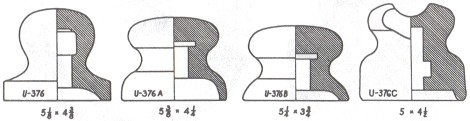

David Adams first reported to me a very unusual

cable-top insulator (see the drawing and photos below) which we have assigned

U-376C. Actually, Bill Rosato and Claude Wambold made the discovery in an

abandoned steel mill built in 1906 by U.S. Steel in McKeesport, P A. They were

walking through one of the old buildings when they found a small pile of these

insulators on the floor with some hollow metal pins laying around them. Bill

relates that they each kept one of the insulators, but they did not collect any

of the pins. Bill did not remember for sure what the pins looked like except

that they were hollow and had a spring loaded piece that protruded out the side

of a hole in the pin that apparently would have fit inside the groove in the pin

hole. David purchased Claude's insulator and I later acquired the one that Bill

found. Unfortunately, the mill site has been completely leveled, so these two

specimens may be all that survived.

It would have been great to get one of the pins to see just how this

insulator was meant to work. The internal groove in the pin hole suggests that

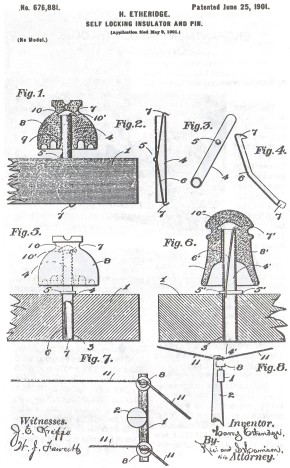

it may be related to the Etheridge patent 676,881 granted on June 25, 1901,

except that the pin is a slightly different design. The Etheridge patent styles,

U-376, U-376A,and U-376B used a pin made from a hollow tube with a protruding

ring to keep the pin from falling through the hole in the crossarm. A flat

spring-metal strip with bent ends fits inside the hollow tube (see copy of

patent drawing at the end of this article). The bottom bent end protruded out of

the bottom of the tube to prevent the pin from being lifted out of the hole in

the crossarm, and the top bent end protruded out of the top of the tube engaging

the groove in the insulator pin hole to prevent the insulator from slipping off

of the pin, but also allowing the insulator to rotate freely on the pin. By

simply inserting a screwdriver inside the bottom of the hollow pin, the flat,

spring-metal clip could be disengaged from the groove in the pin hole, thus

allowing the insulator to be easily removed from the pin.

Note that each of the

three Etheridge patent styles (shown below) have the pin hole groove at the top

of the pin hole and that the groove in the pin hole of U-376C is near the

bottom. The different position of the groove could simply be a change needed

to accommodate the cable-top design. In each case, this groove is located in the

thicker part of the insulator body -- the thicker part for the cable-top style is

naturally near the bottom of the pin hole, which necessitated a design change

for the securing mechanism in the hollow pin.

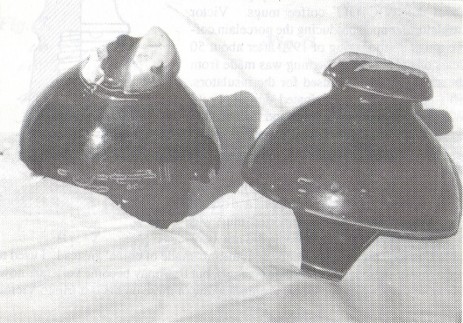

The two photos below show

the U-376C that I got from Bill. While David's specimen has a brown glaze, my

specimen has a very pretty, mottled, mustard-yellow and orange glaze identical

to Thomas M-4415 specimens which have 6 to 10 rings under the top skirt. Indeed,

U-376C is illustrated in the 1907 Thomas catalog! All six dimensions given in

the catalog match the specimens of U-376C, so there is no doubt that Thomas

made this item. U-376A and U-376B were illustrated in the 1904 and 1907 catalog.

These specimens have a darker, mottled, mustard-yellow glaze with an occasional

blotch of the same orange. They were probably made earlier than U-376C albeit

circa 1901-1905. It is interesting to note that the wide unglazed surface around

the bottom of the pin hole shown in the photo below is identical on all of the

specimens of U-376A, U-376B, and U-376C.

U-376 is very odd in many respects. The only known specimen was not made by

Thomas. It has the clear incuse marking on side of the crown: "LIMA, N.Y."!

! Underneath between the skirt edge (firing rest) and the pin hole is

the scratched marking: "No 1"! Making it even more unique is the

glaze. The glaze is a light blue with dark blue specks all over the surface and

inside the pin hole!

Ken Willick continues to send in many interesting reports.

Since Ken lives in Lima, NY, in the heart of porcelain country, he has a lot of

opportunity for finding good porcelain.

He reports finding three Imperial

U-934's along the original Niagara Falls to Buffalo power line. This line made

history when it was put in service on November 15, 1896 at 11,000 volts. This

was the first significant power generated by Niagara Falls. Fred Locke won the

stiff competition to supply the insulators, U-937, which were made for Fred by

Imperial Porcelain Works. These were later changed out with U-934 and again

circa 1900 with U-966 when the line was upgraded to carry 22,000 volts, The

photo below shows Ken's most dramatic find along this old line, two badly

broken, brown U-966's made by Imperial Porcelain Works. One of them has a clear

Imperial crown marking and the date stamp: "4-16-02"! !

Ken sent the photo shown below of a Lapp helical post. The insulator

has six separate grooves which start at the top under the tie-wire groove and

spiral down the sides to form helical grooves. The helical post was designed to

be used in contaminated and fog prone areas. According to the Ohio Brass patent

2,155,848 for the helical post insulator, the helical design would produce an

even voltage gradient across the entire insulator, and the downward slope of the

side petticoats would direct water away rather than run down the grooves. This

Lapp specimen appears to not have the downward projecting side petticoats as

described in the Ohio Brass patent. Lapp may have designed the helical grooves

as an aid in washing the surface.

Ken found a different Fred Locke pony while

digging in the Victor dump. It is significantly larger than either the U-38 or

U-39 so we will assign it the new number of U-39A.

Ken also sent in a newspaper

article about the "VICTOR" coffee mugs. Victor Insulators stopped

producing the porcelain coffee mugs in the spring of 1990 after about 50 years

of production. The mug was made from the same porcelain as used for the

insulators. This durable design originated during World War II for use on Navy

ships and later for the Army. These mugs are incuse marked "VICTOR"

underneath. Imports from China put pressure on sales, so about five years ago,

"MADE IN U.S.A" was added to the marking, but the company finally

conceded to imports and ceased production. The Chinese imported mug was marked

"China", but most people did not associate this with the country,

thinking it meant "made of china" instead. I used to see a few of

these mugs at insulator shows, but they may become very rare now. I believe that

Daniel van Beers acquired a few of these on his last trip to Victor.

Medium Image (137 Kb)

Large Image (375 Kb)

|